- Innovations

Splicing Capability

Splicing Capability

|

We Offer Improved Splicing Capability for Solid and Hollow Profile SealsPrecision extrusion and spliced products offer an ideal, cost-effective sealing solution for many applications. These include low-closure force seals, large diameter profiles that cannot be molded, hollow cross-section cord or requirements for non-standard O-rings and other extruded profiles with an inside diameter larger than 2.500 inches. |

Product Capability:

Splicing and fabrication capabilities continue to expand:

|

|

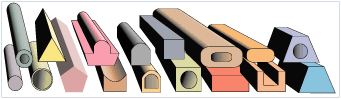

Profile Cross Sections Valley Seal offers an almost unlimited variation of cross- section profiles. Shown below are only a few of the more common extruded profile configurations currently available.  |

Target Markets and Potential Applications

|

|