- Products

-

Sealing Solutions for Communications Equipment

Sealing Solutions for Communications Equipment

|

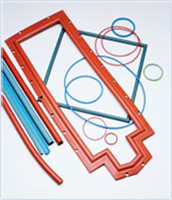

Sealing Solutions for Communications EquipmentCommunications sealing applications present many unique challenges. Environmental sealing is not as simple as just keeping water out of an enclosure. Due to varying environmental conditions, chemical reactions between the environment and the enclosure must also be considered. Harsh environmental conditions such as corrosive coastal air or flooding make sealing sensitive electronic components of prime importance. The long life expectancy of equipment also mandates that premium sealing grade elastomers be used. The low closure force properties of a hollow spliced seal allow it to be used in areas where a solid dense seal cannot perform. Enclosures manufactured from plastic or thin metal tend to warp or crack when subjected to large seal loads. Fasteners and hinges used to hold the enclosure shut may also be excessively stressed by seal closure loads. Die cast enclosures can have large tolerance stack-ups or porosity in the groove which is often difficult to seal. A hollow spliced ring in these applications will solve most tolerance stack-up and porosity problems because of its ability to be compressed more than solid cross-sections and better conform to imperfections of the groove. Read More |

|

Low Closure Force, Foam-BasedSOFT-SHIELD gaskets provide choices in price and shielding performance, Available in lengths, strips and die-cut parts. Materials include conductive fabric, foil/fabric, conductive yarn and knitted wire jackets over foam cones. Read More |

|

Metal GasketsWire mesh EMI gaskets include knitted mesh stripes, mesh frame gaskets, compressed mesh and wire mesh with elastomer cores. SOFT-SHIELD gaskets meet the needs of low-cost, low closure-force shielding applications. Read More |

|

Heat SpreadersT-WING and C-WING heat spreaders provide a low-cost, effective means of cooling IC devices in restricted spaces where conventional heat sinks aren’t appropriate. They typically provide junction temperature reduction of 62F (20C) when applied on microprocessors and cache chips in laptop PCs and other high density, handheld electronics, and on disk drives. They’re easily added by peel and stick application. Read More |

|

Phase-Change Thermal Interface MaterialTHERMFLOW materials are thermally enhanced polymers designed to minimize the thermal resistance between power dissipating electronic components and their associated heat sinks. This low thermal resistance path maximizes heat sink performance an improves the reliability of microprocessors, memory modules, DC/DC converters and power modules. Read More |

|

Thermally Conductive Adhesive TapesTHERMATTACH tapes are double-sided adhesive systems that replace mechanical fastners for bonding heat sinks to ceramic or metal packages. They provide excellent thermal, mechanical, environmental and chemical properties. . Read More |

Thermally Conductive Gap Fillers

|

Thermally Conductive Fully Cured Dispensable Gap FillersTHERM-A-GAP Dispensable Gap Fillers are ideal for applications where gap filling pads overstredd component solder joints and leads which can result in catastrophic system failure. These materials are highly conformable, one component, pre-cured silicone gels that can be dispensed to fill large and uneven gaps in electronics assemblies. Read More |

THERM-A-GAP elastomers are used to fill air voids between PC boards or high temperature components and heat sinks, metal enclosures and chassis. The exceptional conformability of these advanced materials enables them to blanket highly uneven surface, transferring heat away from individual components or entire boards and allowing chassis pats to be used as heat spreaders where space is restricted.

Thermally Conductive Insulators

CHO-THERM thermally conductive, electrically insulating interface materials consist of silicone, fiberglass and ceramics. They are produced with numerous thermally conductive, dielectric fillers that transfer heat from electronic components to heat sinks or other heat sinking devices.

Thermal Greases and Gels

Our thermal grease is formulated to efficiently conduct heat and fill the voids between hot components and heat sinks. These are non-curing, dispensable, highly conformable materials which require no cure cycle or mixing and dispenses to fill highly variable tolerances in electronics assemblies. The material is thermally stable. They require virtually no compressive force to deform under assembly pressure leaving solder joints and leads stress free.