- Products

-

Integral Seals

Integral Seals

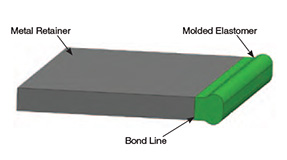

The Integral Seal is so named because it effectively integrates a

stamped or machined metal or molded plastic retainer with a moldedin-

place rubber sealing element to create an extremely versatile

sealing device.

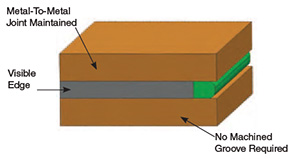

The Integral Seal is custom designed, versatile and provides similar performance benefits seen with Parker’s Gask-O-Seal. The Integral Seal lends itself to space constrained applications where overall seal thickness may be of primary concern. Integral Seals can be manufactured in thickness as low as 0.012". The Integral Seals design also lends itself to high volume manufacturing methods making it a cost competitive option for high volume sealing applications. As shown below, the rubber sealing element is molded, and mechanically and/ or chemically, bonded in place to the edge of the retainer.

The Integral Seal is custom designed, versatile and provides similar performance benefits seen with Parker’s Gask-O-Seal. The Integral Seal lends itself to space constrained applications where overall seal thickness may be of primary concern. Integral Seals can be manufactured in thickness as low as 0.012". The Integral Seals design also lends itself to high volume manufacturing methods making it a cost competitive option for high volume sealing applications. As shown below, the rubber sealing element is molded, and mechanically and/ or chemically, bonded in place to the edge of the retainer.

| Features | Product Image | Benefits |

| Molded in Place |  |

Sealing element precisely and permanently molded in place, allowing for ease of assembly. Secondary machining in mating hardware is not required to reduce hardware costs. |

| Visual Detection |  |

Can be visually inspected to verify proper assembly. The integral seal concept offers the ultimate in quality assurance and joint integrity. |

| Bolt Retention |  |

The rubber can be molded into the bolt holes for positive pre-assembly gripping and transporting. |

| Retrofit or New |  |

The Integral Seal can be retrofitted to existing O-ring grooves or counterbores or it can be adapted to grooveless mating surfaces. |

| Point Loading of Seal |  |

Permits reduced flange thickness, smaller bolts and bolt circle. The force required to load the Integral Seal metal to metal can be predetermined with closely controlled crown height and FEA. |

| Alternative Load Path |  |

No retorquing required due to metal to metal contact. The load path is established through the metal retainer assuring positive closure and optimum bolt loading. |