- Innovations

-

ThredSeal® Fastener Seals

ThredSeal® Fastener Seals

|

Application: ThredSeals® are safe, reliable and reusable seals for threaded devices. They are designed to seal directly against threads, without any special requirements. They are self-centering, non-directional and affordable. ThredSeals® can also offer considerable savings because they enable the use of low cost standard fasteners and full threaded fittings. They are easily assembled without need for special skills or tooling – simply push them on with a slight twisting motion and tighten the fastener. |

Features :

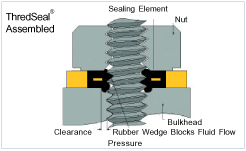

Unlike other cure-in-place thread sealing methods, ThredSeals® are mechanical, not chemical in application. They can be easily assembled and removed, do not require set up cure time, and are easily parted from contacting surfaces without special tools or chemicals. This enables easy access to the sealed areas. ThredSeals® seal at the recommended pressure and temperature levels by utilizing the bolt threads to form a contained elastomeric dam. If the elastomeric element is not damaged to the extent of tearing or rupturing, the seals are reusable. Close visual inspection after each removal is recommended, and the use of cover washers will reduce the possibility of tears or breaks in the rubber, as well as provide adequate seating surfaces for the nut.

Design Requirements:

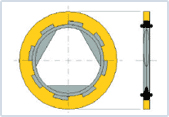

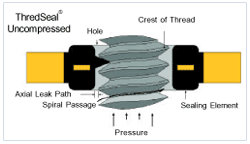

ThredSeals® work by blocking all leak paths in a threaded fastener. They are used with standard bolts or screws and generally are seated on the nut side of the fastener. Unlike sealing directly underneath the bolt head, the nut side of the fastener has an additional spiral leak path, created by the threads, which will permit the fluid to wind its way through the helix. ThredSeals® have three wedge shaped protrusions on the inside of the seal. Since all standard screw threads have only a single V-shaped spiral channel, one of these wedges will always be in position to block the flow of fluid through this channel.

|

Threadlocker Anaerobic Adhesives (TL Series)Parker TL Series Anaerobic Adhesives are liquid resins that cure (in the absence of air) when placed in contact with metallic or threaded parts. Read More

|

Surface Treatment Products

Applications:

Retain and lock threaded parts-

Parker TL Anaerobic sealants are liquid resins that cure when placed in contact with metallic or threaded parts. They provide high resistance to pressure, vibration, and fill 100% of gaps between parts. Parker Thread-blocker sealants can replace PTFE tape in threaded fittings, eliminating the risk of tape tear and the possibility of tape ending up in their pumps and filters.Gasket sealant for flange

Parker Anaerobic GG Flange sealants are typically used as a form-in-place gasket on rigid flange connections, such as gearboxes, engine casings, pumps, cover shafts, thermostats, compressors, transmission housings, and axle covers. When applied these compounds quickly cure in the absence of air while excess product will remain liquid. They are compatible with oils and most hydraulic fluids.Assembly of components

Parker RC series Anaerobic Adhesives are liquid resins that cure when placed in the contact with metallic or non-threaded parts with small gaps. They allow for larger tolerances between parts and can be a substitute for precision machining, resistance to water, fuel, gases, oils and other chemical products. Parker adhesives have very high strength and help prevent leakage and loosening of parts caused by vibration.Parker Instant Adhesive for metals, leather, rubber, and plastic

based on cyanoacrylate technology, Parker adhesives in the IA series are made up of single-component adhesives available with a low, medium and high viscosity. All three types have fast setting time, offer high tensile strength and do not require pre-mixing. These general purpose Parker adhesives bond to a variety of surfaces such as metals, rubbers, ceramics, leather, wood, and most plastics. These adhesives are very easy to apply and can be used in manual, semi-automatic, and automatic applications. |

Key Benefits:

|

|